We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

The environmental impact of refrigerants has been a growing concern for decades. As major transformations for refrigerants within the industry emerge, phasing down outdated and climate-damaging refrigerants will be a continuous challenge for the industry in the years to come. Technicians and consultants in the HVAC industry must have a thorough understanding to be well-prepared for the new era of refrigerants. As always, to help you understand what’s coming, let’s delve into the major changes that will be made to the lifeblood of HVAC systems.

Why You Should Care About HVAC Refrigerant Trends in 2024

Regulations and policies concerned with the environment are always global, not limited to one single industry or region.

The European Union's F-Gas Regulation is a testament to its commitment to environmental protection. This regulation seeks to curtail the use of fluorinated greenhouse gases, commonly known as Hydrofluorocarbons (HFCs) by 95% by 2030 compared to 2015, going down to zero by 2050.1)

1) European Commission, ‘Commission welcomes agreement on new legislation to prevent 500 million tonnes of emissions from fluorinated gases and ozone depleting substances’ (2023),https://ec.europa.eu/commission/presscorner/detail/en/ip_23_4781

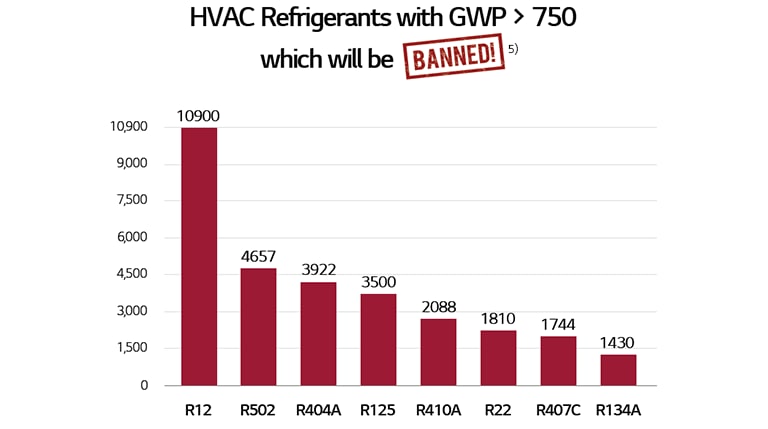

Starting in 2027, plug-in and other self-contained systems under capacity 50kW will be prohibited from using F-gases with a Global Warm Potential (GWP) of 150 or more. Additionally, single-split systems containing less than 3 kilograms of F-gases with a GWP of 750 or more will be banned in 2025.2)

2) https://www.rehva.eu/rehva-journal/chapter/update-on-the-f-gas-regulation-negotiations-the-shift-to-very-low-gwp-refrigerants

Further restrictions will be implemented, Air-to-Water Split systems will be limited from 2027 and Air-to-Air Split Systems from 2029 to using F-gases with a GWP below 150. All split systems with a capacity of 12 kW or more are limited to using F-gases with a GWP below 750 from 2029.*

*According to the recent announcement of the F-gas regulation revision, the final agreement has not been concluded.

Across the Atlantic, North America has been equally proactive. The EPA’s (Environmental Protection Agency) SNAP (Significant New Alternative Policy) program set forth clear guidelines to phase out ozone-depleting substances. The EPA is mandated to reduce the production and usage of HFCs by 85% by 2036.3)

Starting in 2025, the EPA will prohibit the sale of new domestic and commercial air conditioning and heat pump equipment that utilizes refrigerants with GWP of 750 or higher. This ban will extend to VRF systems on January 1, 2026. For air conditioning chillers, the ban is proposed to take effect even sooner, starting on January 1, 2024.4)

3) EPA’s Proposed Refrigerant Ban Prompts HVAC Industry Response,

https://www.achrnews.com/articles/152969-epas-proposed-refrigerant-ban-prompts-hvac-industry-response

4) US EPA considers R410A ban from 2025, https://www.coolingpost.com/world-news/us-epa-considers-r410a-ban-from-2025/

5) https://insights.globalspec.com/article/4819/low-gwp-refrigerants-understanding-gwp-ghg-odp-and-climate-change

Next-Generation Refrigerants

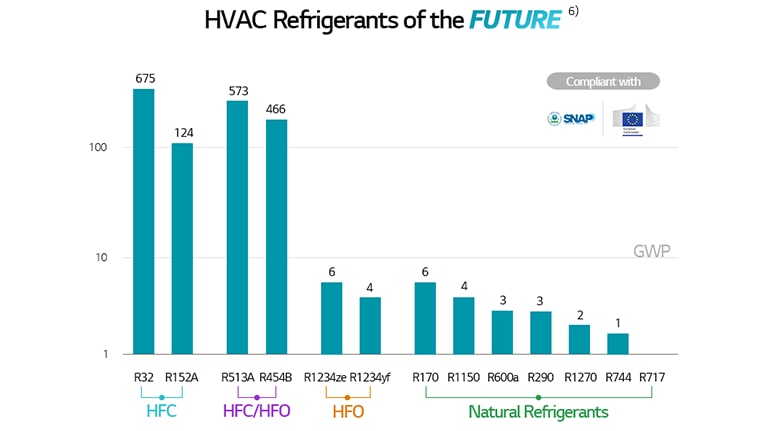

So, which future refrigerants would you have to consider using in the coming years? We did our best to break them down into three categories according to their compositions, and in order of which highest to lowest GWP.

Hydrofluorocarbons (HFCs), and hydrocarbons (HCs) are more prevalent, each offering different benefits and challenges in terms of efficiency, environmental impact, and safety. R32 is a good example, offering a trifecta of benefits: enhanced efficiency, reduced GWP, and recyclability.

Hydrofluorocarbons (HFCs), and hydrocarbons (HCs) are more prevalent, each offering different benefits and challenges in terms of efficiency, environmental impact, and safety. R32 is a good example, offering a trifecta of benefits: enhanced efficiency, reduced GWP, and recyclability.

Natural refrigerants are the real game-changers. Substances like CO2 (R744), ammonia (R717), and hydrocarbons such as propane (R290) and isobutane (R600a) are making waves in the industry. Their minimal GWP makes them standout candidates for future HVAC systems.

6) https://insights.globalspec.com/article/4819/low-gwp-refrigerants-understanding-gwp-ghg-odp-and-climate-change

Stay Ahead of HVAC Refrigerant Trends

As the HVAC industry transitions to new refrigerants, the industry will experience several notable changes. Falling behind this upcoming refrigerant trends with lower Global Warming Potential (GWP) will inevitably require implementing new systems or replacing the existing systems which will accompany difficulties financially and physically.

It is important to stay ahead and lead with the trends and regulations as soon as you can. If you’re one of the first to bring natural refrigerants to the table, for example, not only the HVAC systems will be compliant with the new environmental policies but also as some newer refrigerants are often more energy-efficient, it can lead to lower energy bills and improved system performance.7)

7) https://ec.europa.eu/commission/presscorner/detail/en/ip_23_4781

LG Adapts to Stay Ahead of Refrigerant Trends

LG is demonstrating its leadership in the HVAC industry by adopting more efficient refrigerants with superior performance and lower GWP. From general air conditioning products to hot water solutions, LG’s strategic transitions not only comply with regional environmental regulations but also set a benchmark for sustainability and efficiency in the HVAC industry.

LG’s commitment extends to pioneering research in various areas, including the development of heat exchangers designed to reduce refrigerant volume and the engineering of systems that take into account the unique cycle characteristics of each alternative refrigerant. As we transition to environmentally-conscious alternatives, we're not just ensuring a comfortable present but also championing a sustainable future for generations to come.

*Products and solutions may vary according to country and operating conditions.

Contact Us

Please contact us for more information, and we will get in touch with you soon.