We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

We cut carbon

not create it

Business as usual, is not

business as usual anymore.

We’re changing the way we operate

to achieve carbon neutrality

and ensure all operations use

100% renewable energy by 2030.

Key progress

Key progress

Our ambitious 2030 carbon neutrality goal means taking immediate action. Through continuous process

improvement, we're reducing more greenhouse gas emissions in the entire manufacturing process from

production to use.

Towards

carbon neutrality

-

0%2023

-

0%2024

-

Carbon

neutrality*2030

-

0.0%2023

-

0.0%2024

-

0%2030

-

0%2050

- *Scope 1 & 2: Reduce an absolute amount of 54.6% by 2030 compared to 2017 (SBTi verification completed in 2021)

How to achieve carbon neutrality

Towards carbon neutrality

We’re committed to a greener future, discovering and creating ways

to reduce carbon emissions through sustainable practices.

-

Greening our production:

Cut emissions by 2030

-

Powering progress:

100% Renewable by 2050

-

Certifiably green:

Securing emission reductions

- Greening our production:

Cut emissions by 2030 - In order to achieve our goal for reducing greenhouse gas emissions generated during the production phase of our products, we are introducing energy-efficient facilities and carbon emission reduction devices throughout our production process.

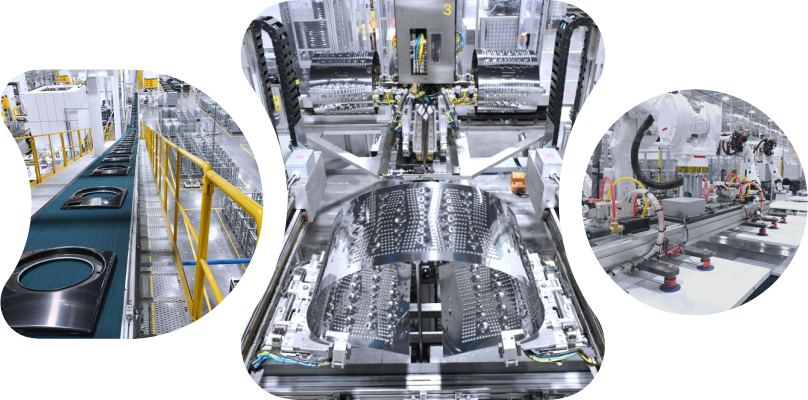

- LG Smart Park in Changwon, named a Lighthouse Factory by the World Economic Forum, is playing a major part in curbing GHG emissions during production, while also elevating energy efficiency by 30 percent compared to the company’s previous Changwon facility. Among the many innovations at LG Smart Park helping to shrink the company’s energy footprint are state-of-the-art energy management solutions such as the Energy Storage System (ESS) and Building Energy Control (BECON).*

- We’re also carrying out emission reduction activities by investing in SF6 (sulfur hexafluoride) gas treatment facilities. We reduce process gas emissions by 93% by operating the facility to reduce SF6 process gas emissions from high-efficiency solar panel production.**

- *Energy input per produced unit and greenhouse gas emissions per produced unit have decreased by 30 percent, comparing the figures from the year 2020 to 2021 according to the lighthouse site visit report by World Economic Forum.

- **LGE announced the withdrawal from the global solar panel business at the end of June 2022, and solar panel data related to this report represents the past performance.

- Powering progress:

100% Renewable by 2050 - We are making impressive strides in its renewable energy endeavors, with a strong focus on expanding its business in this sector. In 2022, the U.S. production/sales subsidiaries and logistics, as well as the production subsidiaries in Brazil, underwent a complete transition to 100% renewable energy. Noteworthy progress has already been made, as we have procured 58,961MWh of Renewable Energy Credit in the US and secured 31,946MWh of renewable energy through hydroelectric power contracts in Brazil.

- To realize these goals, we have formulated a comprehensive long-term plan that takes into account the current regulatory landscape and the state of its business sites in Korea and other countries. The plan encompasses various viable options such as green tariffs for purchasing renewable energy, acquiring Renewable Energy Credits (REC), and engaging in third-party Power Purchase Agreements (PPA).

- A notable achievement has been accomplished at LG Smart Park in Changwon, Korea, where the company successfully established the first-ever direct Power Purchase Agreement in the country, securing a robust power generation capacity of 2.3MW. These exceptional efforts not only underscore LG's unwavering dedication to sustainability but also position the company as a frontrunner in the renewable energy industry.

- Certifiably green:

Securing emission reductions - A certain amount of carbon emissions is inevitable. To balance this, we reduce carbon emissions in other areas to stay carbon neutral and keep our carbon emissions at zero. We strives to develop high-efficiency products that only emit as much carbon as they can reduce.

- We received a carbon emissions allowance from the UNFCCC Executive Committee by producing and providing innovative, high-efficiency fridges in India. The key technology of high-efficiency fridges is the inverter linear compressor. It controls the system more precisely than a typical compressor, operating the motor only when necessary, which improves energy efficiency and performance.

- In this way, we're taking eco-friendly action through a virtuous cycle of securing carbon emissions with high-efficiency fridges produced in India, and investing the profits into greenhouse gas reduction projects in Korea.

-

564,726 tons

We secured the right to release 564,726 tons of carbon from 2018 to 2020

Home appliances

manufacturing factory

LG Lighthouse Factory

Lighting the way towards sustainability

The LG Lighthouse Factory is the first household appliance manufacturing facility in Korea and

consumer electronics factory in the US to adopt eco-conscious manufacturing practices. Particularly,

the LG Smart Park Factory in Changwon, Korea, has garnered recognition for successfully implementing

various measures to reduce environmental impact.

-

LG Smart Park,

Home Appliances'

first lighthouse factory - Changwon, Korea

-

- Changwon LG Smart Park garnered international acclaim in 2022 as the first 'lighthouse factory' in the Korean home appliance industry. The facility places a strong emphasis on eco-conscious manufacturing and has implemented a range of measures to reduce its environmental impact. These include reducing greenhouse gas emissions, utilizing eco-friendly production technology, and recycling waste heat, leading to an impressive 30% reduction in energy consumption.

-

- In collaboration with GS EPS, the factory is installing a rooftop power plant to advance its renewable energy objectives. By 2025, the factory will manufacture and install 10,000 solar panels, generating over 10% of the building's annual power consumption. This ambitious project is expected to result in an annual reduction of 3,000 tons of greenhouse gas emissions, equivalent to planting 20,000 trees per year.

- Moreover, the factory employs an Energy Storage System (ESS) to mitigate peak loads. The ESS efficiently stores electricity during off-peak periods and releases it during high-demand periods. This collaborative endeavor with Korea East-West Power and LG Electronics not only reduces electricity costs but also significantly contributes to the reduction of greenhouse gas emissions. By optimizing electricity usage during low-rate late-night hours, the system is projected to yield substantial savings of KRW 77.4 billion over 15 years. Furthermore, the ESS has the capability to replace 15% of the facility's daily power consumption, further enhancing its commitment to sustainability.

-

LG Tennessee factory,

the first lighthouse factory in US - Tennessee, USA

-

- LG Tennessee factory has earned the prestigious "lighthouse factory" designation from the World Economic Forum. It is the first consumer electronics factory in the US to receive this recognition. The factory incorporates advanced technology and automation, producing home appliances like washers and dryers. With cutting-edge digital systems, including AI, big data, IoT, and robots, it meets market demand with local production.

-

- The facility takes pride in its fully automated logistics system, where 166 automated guided vehicles and robots handle complex tasks. The factory has been running on 100% renewable energy since 2021, leading to an impressive 63% reduction in carbon emissions. Additionally, the factory uses the BECON*(Building Energy Control) solution to maximize energy efficiency in power, steam, and heat supply. Completed in 2018, this factory exemplifies our manufacturing expertise and dedication to shaping the future of global manufacturing.

- *As a building energy management solution, BECON provides instant access to energy information and current status, allowing for control and optimization tailored to each facility type. It also offers customized solutions to match the unique characteristics, facilities, and environment of the building.

Collective action

Greater impact

Net-Zero House, created by LG, is a space that

promotes a sustainable future for our planet. It

shows customers how their everyday appliance usage

can have a positive impact on the environment.

- Life with Net-Zero House

-

We reveal our vision of a more sustainable way of life with the

“Net-Zero House”. The comprehensive LG Home Energy Platform is a total

solution for household energy management, heating and cooling that

includes the Energy Storage System (ESS) and the Therma V™ R290

Monobloc air-to-water heat pump (AWHP). By combining the LG ESS and

LG Therma V AWHP, the platform offers efficient heating as well as user-

friendly energy management – including all spectrum from production

and storage to usage and conservation. - LG Therma V AWHP

Reducing carbon at home - The LG Therma V delivers year-round indoor comfort and, just as importantly, uses energy more efficiently than a traditional heating and cooling system. Targeting the decarbonization trend, the Therma V R290 Monobloc helps users to lower their household’s carbon footprint while extracting heat from the surrounding air by adopting R290 refrigerant, which boasts a Global Warming Potential (GWP) of just three. It is also able to produce the high temperature of water that can be produced with existing old radiators.

- Easily integrated with LG’s AWHP, the ESS (Energy Storage System) offers an innovative and convenient way to maximize the efficiency of a home’s renewable energy use, and serves as a back-up power source in the case of blackouts. Surplus energy can be stored in the ESS battery and diverted to the AWHP’s integrated water tank during the daytime, when solar energy production is at its peak. In the evening, when energy consumption is typically high, the ESS utilizes the stored energy to provide hot water and to power home appliances, boosting energy efficiency and energy self-reliance. Should a power outage occur, the ESS can help to keep essential elements, such as heating, refrigeration and lighting, up and running. The energy surplus is stored in the ESS for later use, or sold to a contracted electricity provider.

- In addition to the Therma V, the ESS is able to integrate with a wide range of Home Appliances, including the washer, refrigerator, oven, dishwasher and Styler, and even with the electric vehicle (EV) charger.

-

-

ThinQ

Manage your home energy - The Home Energy Platform is compatible with LG ThinQ Energy, an intuitive-to-use energy management solution, enabling users to control all of their smart appliances, manage the HVAC system, and monitor energy storage and consumption, from almost any location with their smartphones. Additionally, appliances with the Energy Saving Mode, which can be easily accessed via the ThinQ app, further help in using energy efficiently.*

- * Tested by LG internal lab. Based on the assumption that running twenty drying cycles a month, the amount of energy used for drying 3kg load using Cotton+ cycle under Energy EcoHybrid™ (183kWh) with a dryer model RH80V9AVHN saves up to 77kWh per year, compared to using Cotton+ Cycle under Time EcoHybrid (260kWh).

-

Together,

we can make a difference

The climate crisis is a serious challenge that

requires all of us to work together. We're always

striving to find solutions, and you're welcome to

join us. Together, we can build a brighter future!