We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

Small movements make big waves. This is precisely the case with the HVAC system project for the Geneva Tower project managed by LG Algeria. The 19-floor Geneva Tower is part of the larger DAHLI Towers project in Algiers and is one of the most remarkable landmarks in the area. DAHLI DEVELOPER, the owner of the building, required high efficiency for energy conservation, flexibility for convenient installation, and comprehensive system control to ensure the comfort of occupants. For this project, LG recommended the 284hp Multi V solution. Let’s take a look at how the LG Multi V was able to win over this customer in Algeria.

Energy Conservation & Operating Cost Savings

Geneva Tower is an office building that must stay operational all year long and requires high efficiency to reduce energy consumption and costs. The LG Multi V 5 is an integrated solution that combines advanced technologies for high-rise buildings to provide energy efficiency while improving operational costs. Proprietary LG technologies allowed Geneva Tower to meet its efficiency and reliability goals.

The LG Ultimate Inverter Compressor makes this efficiency possible while enhancing reliability. Vapor Injection enhances efficiency with two-stage refrigerant compression. Smart Oil Management utilizes oil sensors to run oil recovery when further efficiency is in demand and HiPOR™ decreases energy loss with direct oil return. In addition, Dual Sensing control senses both temperature and humidity, offering economical and comfortable operation.

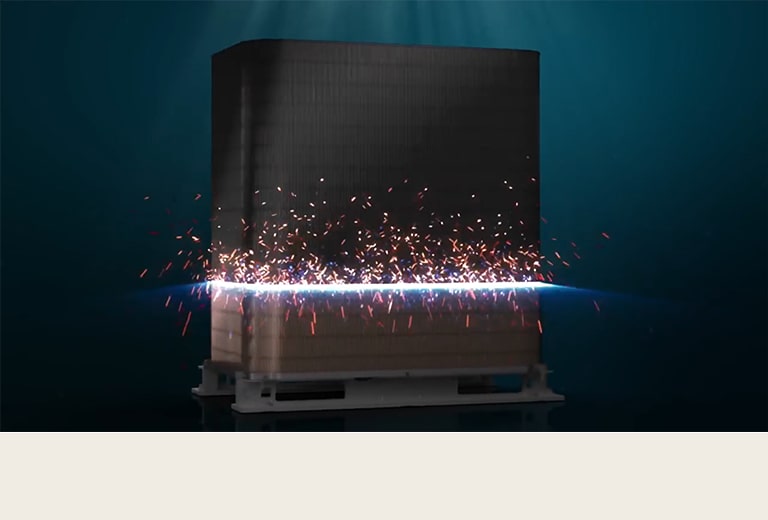

Improved Durability with Black Fin Technology

Every building is exposed to the elements of its environment, which also leaves the outdoor HVAC units exposed as well. Prolonged exposure to elements such as seawater mist and pollution causes severe corrosion to the heat exchanger of an HVAC system and profoundly impacts system efficiency and reliability. With Geneva Tower being located in close proximity to the sea, the facility’s HVAC units are vulnerable to corrosion due to salt-laden seawater mist exposure. LG Black Fin coating on the Multi V 5 heat exchanger provides strong protection from corrosive materials and the hydrophilic film decreases moisture buildup on the component. Not only does Black Fin technology ensure prolonged system efficiency but also extends the lifespan of the product.*

*Verification of corrosion resistance performance

- Declared by TUV Rheinland

- Test Method B of ISO21207

- Test condition : Salt contaminated condition + severe industrial / traffic environment (NO2 / SO2)

LG's black fin

Refrigerant Leakage Safety

Transitioning from a chiller system to a large-scale VRF system like the Multi V 5 requires extensive refrigerant piping to deliver enormous amounts of refrigerant to indoor units. While these piping systems are safe and secure, administrators had concerns about the possibility of refrigerant leaking into the facility. To address these concerns at Geneva Tower, a solution was provided to detect refrigerant leakage in real-time. LG provided a Refrigerant Leakage Detection solution for Geneva Tower to ensure a safe environment throughout the facility. This solution uses sensors to detect when the refrigerant concentration exceeds 6,000ppm for 5 seconds or more. When this concentration is detected, the relevant indoor units stop operating, with an optional alarm or notification light that will notify users and administrators immediately.

LG's black fin

Comfort for Residents and Peace of Mind for Project Administrators

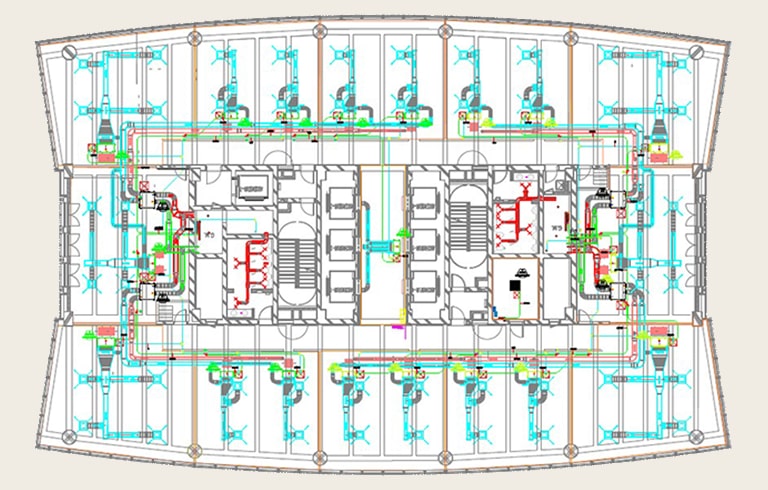

Project administrators also received full support from LG throughout the entire project through onsite consultation, inspections of all equipment, and thorough testing before, during, and after installation. LG’s LATS CAD support in the design stage of development allowed for fast and accurate system configuration. It provided installers with estimations for refrigerant piping diameters and lengths in line with LG design guidelines. LG truly demonstrated its commitment to service and performance throughout the project.

For this high-rise office building, efficiency, flexibility, and durability were key. LG was able to work closely with local partners, providing support through all stages of project development. With 3 years of continued support and development of trusting relationships, LG was able to deliver a system that met the needs of the customer and improve the quality of this local landmark in Geneva Tower.

Contact Us

Please contact us for more information, and we will

get in touch with you soon.